Choosing the right grease for your bench vise is crucial for its performance and longevity. The best grease ensures smooth operation and protects against wear and tear.

Whether you’re clamping down on a Wilton General Purpose Bench Vise or rotating a Yost Vises 750-DI, the right lubricant makes all the difference. From the quick-release action of a MYTEC Drill Press Vise to the secure grip of a Tipton Ultra Gun Vise, every tool benefits from proper maintenance.

Likewise, for bike enthusiasts, a well-greased Get Out! Bike Repair Stand can enhance the repair experience. And for firearms aficionados, the Tipton Best Gun Vise demands high-quality lubrication. With options like Super Lube-21030 Synthetic Grease and Permatex 80345 White Lithium Grease, your maintenance routine is incomplete without the perfect grease. Lucas Oil’s White Lithium Grease offers a reliable choice for those needing larger quantities. Let’s explore the top contenders to ensure your bench vise operates at its best.

Table of Contents

Wilton General Purpose Bench Vise

The Wilton General Purpose Bench Vise is a versatile and durable tool designed for a variety of applications in your workshop. With a sturdy build and precise engineering, this bench vise offers exceptional clamping strength for woodworking, metalworking, and other tasks that require a solid grip.

Pros:

- 4″ Jaw Width provides ample space for a wide range of projects.

- 3″ Max Jaw Opening ensures versatility for clamping different materials.

- 2-1/4″ Throat Depth offers deep reach for various workpiece sizes.

- Constructed by WMH Tool Group, known for their quality craftsmanship.

- Bold blue color makes the vise easy to locate in a busy workshop.

- Compact dimensions and a weight of 15.0 pounds make it manageable to handle and mount.

Cons:

- May be considered heavy if frequent repositioning is required.

- Some users might find the 3″ Jaw Opening limiting for larger projects.

The Wilton General Purpose Bench Vise is more than just a simple tool; it’s an investment in quality and efficiency for your workspace. Its robust design, backed by the trusted Wilton brand, ensures that it can withstand the demands of heavy-duty use while maintaining precision. The blue color is not only visually appealing but also practical, allowing for easy identification among other tools.

Overall, this bench vise’s balance between size and power makes it an excellent choice for both professional craftsmen and hobbyists. Whether you are dealing with wood, metal, or any other material, the Wilton General Purpose Bench Vise will prove to be an indispensable part of your tool collection. Its solid construction and thoughtful features are designed to enhance your working experience and improve project outcomes.

To buy this product, click here.

Wen Bench Vise

The WEN Bench Vise, with its 5-Inch size and durable cast iron construction, is a robust tool designed to provide a reliable grip for your workpieces. Equipped with a convenient swivel base, this bench vise offers versatility and ease of use for a variety of projects.

Pros:

- Durable cast iron construction ensures long-lasting performance

- Swivel base allows for positioning at any angle

- 5-Inch jaws provide a strong grip for medium-sized workpieces

- Non-slip texture on the jaws ensures workpieces stay securely in place

Cons:

- Weight of 23.7 pounds may be cumbersome for some users

- Limited opening capacity may not be suitable for larger projects

The WEN Bench Vise is an indispensable tool for both professional craftsmen and hobbyists. The product’s robust construction, featuring cast iron material, provides exceptional durability and strength, handling the stresses of clamping without any signs of wear. The vise’s 5-inch jaws are perfect for a variety of projects, allowing users to securely grip items while they work.

Moreover, the vise’s swivel base greatly enhances its functionality, making it easy to rotate and lock the vise in place at the most convenient angle. This flexibility is a significant advantage when working on complex tasks that require precision. The WEN Bench Vise solidifies its position as a valuable addition to any workshop, offering reliability and versatility to tackle a broad range of tasks.

To buy this product, click here.

Mytec Drill Press Vise

The MYTEC Drill Press Vise, 3.0″ Black, Quick Release Workbench Industrial Vise Clamp is an essential tool for anyone looking to enhance their workbench capabilities. Crafted from high-grade cast steel, this vise clamp is designed for durability and precision. Its quick-release mechanism ensures ease of use, making it a reliable addition to any industrial or home workshop.

Pros:

- Quick release mechanism for easy operation

- Made from high-grade cast steel for durability

- Lightweight design at just over 5 pounds, making it easy to handle

- Black color fits in with most workshop decors

Cons:

- May be too small for larger projects

- Limited to a 3.0″ opening, which may not suit all needs

The MYTEC Drill Press Vise stands out in the market for its robust construction and user-friendly features. The quick-release function is particularly noteworthy, allowing users to efficiently secure or release workpieces with minimal effort. This feature, combined with its sturdy high-grade cast steel construction, ensures that the vise can withstand the rigors of daily use while maintaining precision.

Furthermore, the vise’s lightweight design, at just over 5 pounds, means it can be easily moved and adjusted as needed, without sacrificing stability or build quality. Although it’s designed with a 3.0″ opening, which might limit its use for larger projects, its dimensions make it an ideal choice for most standard applications, offering both professionals and hobbyists a reliable tool for their workbench. Overall, the MYTEC Drill Press Vise is a valuable addition to any workshop, striking an excellent balance between functionality and convenience.

To buy this product, click here.

Yost Vises 750-di Multi-jaw Rotating Vise System

The Yost Vises 750-DI Multi-Jaw Rotating Vise System is a versatile and robust tool designed for both professionals and hobbyists. It offers a unique 2 in 1 multipurpose function, acting as both a bench and a pipe vise, and ensures a secure grip with its swivel base. Constructed from a combination of ductile iron and hardened steel, this large vise is finished in a striking blue color, making it as visually appealing as it is functional.

Pros:

- 2 in 1 Multipurpose functionality allows for varied use

- Secure Grip with the swivel base ensures stability during use

- Constructed from high-quality materials for durability

- Large size provides ample working space for various projects

Cons:

- At 59.52 pounds, it may be too heavy for some users to move easily

- May be overly complex for beginners or those with simple vise needs

When discussing the Yost Vises 750-DI Multi-Jaw Rotating Vise System, it’s important to highlight its remarkable versatility. The ability to switch between bench and pipe vise functions makes this tool a valuable addition to any workshop. The secure grip provided by the swivel base allows users to work with confidence, knowing their materials are held firmly in place. This is a critical feature for tasks requiring precision and safety.

The construction material of the vise, a combination of ductile iron and hardened steel, ensures a long service life and resistance to wear and tear. The blue color not only adds a visual pop to your workspace but also makes it easier to locate the vise among other tools. Although its weight might be a drawback for some, the heft of the Yost Vises 750-DI contributes to its stability and robust performance.

To buy this product, click here.

Get Out! Bike Repair Stand For Maintenance

Whether you’re a seasoned cyclist or a hobbyist, the Get Out! Bike Repair Stand is a must-have for maintaining your bike in top condition. This versatile repair stand is designed for both wall and bench mounting, offering flexibility and convenience for any workspace. Suitable for all bike types including folding, mountain, electric, or road bikes, this stand ensures your bike stays secure while you work.

Pros:

- Flexibility to mount on walls or workbenches

- Compatible with various types of bikes including folding, mountain, electric, or road bikes

- Sturdy clamp to hold the bike securely during repairs

- Space-saving design when not in use

- Constructed by the reputable brand Get Out!

Cons:

- Limited to static use as it needs to be mounted

- May require additional hardware for installation

The Get Out! Bike Repair Stand is an innovative solution for bike enthusiasts looking for a reliable and sturdy work stand. With dimensions measuring 4.299 inches in both height and width, and 14.901 inches in length, it’s compact enough to fit in small spaces yet robust enough to handle various repair tasks. The brand’s commitment to quality is evident in the design and construction of this stand, making it a valuable addition to any cyclist’s toolkit.

In conclusion, the Get Out! Bike Repair Stand shines in its ability to adapt to different environments and the variety of bikes it can support. Although it’s not a portable option and may require some initial setup, the benefits of having a secure and steady stand for bike maintenance are undeniable. For those who regularly engage in bike repair and upkeep, investing in this stand would be a wise decision for long-term bike maintenance.

To buy this product, click here.

Tipton Ultra Gun Vise

The Tipton Ultra Gun Vise stands out in the realm of firearm maintenance, offering a heavy-duty, customizable design tailored for cleaning, gunsmithing, and maintenance tasks. Its non-marring material ensures that your firearm remains unscathed during the maintenance process, making it an indispensable tool for both professionals and enthusiasts.

Pros:

- Heavy-duty construction ensures durability and long-term use

- Customizable design allows for adjustments to fit a wide range of firearms

- Non-marring materials protect the firearm’s finish during maintenance

- Convenient dimensions (Height: 11.0 inches, Width: 10.5 inches, Length: 32.5 inches) provide ample working space

- Portable with a weight of 13.6 pounds, making it easy to move and store

Cons:

- May be pricey for hobbyists looking for a basic vise

- Size may be cumbersome for those with limited workspace

The Tipton Ultra Gun Vise is a game-changer for anyone serious about firearm maintenance. With its heavy-duty and customizable features, it accommodates a wide range of firearms, from rifles to handguns. The inclusion of non-marring materials in its construction is a thoughtful touch, ensuring that your firearm’s finish is preserved throughout the cleaning or gunsmithing process. Its dimensions and weight strike a balance between providing ample workspace and being easily movable, catering to both stationary and on-the-go maintenance setups.

Despite its higher price point, the value offered by the Tipton Ultra Gun Vise justifies the investment, especially for those committed to maintaining their firearms in top condition. While its size might pose a challenge for individuals with restricted space, the benefits of using a vise that is specifically designed for the task at hand cannot be overstated. The Tipton Ultra Gun Vise is a standout product from Battenfeld Technologies, embodying the qualities of durability, functionality, and protection that are essential for effective firearm maintenance.

To buy this product, click here.

Super Lube-21030 Synthetic Multi-purpose Grease

The Super Lube-21030 Synthetic Multi-Purpose Grease is a versatile lubricant designed for a wide range of applications. Its synthetic base ensures superior performance under various conditions, making it an essential item for maintenance tasks.

Pros:

- Highly versatile for multiple applications

- Provides excellent lubrication and protection

- Long-lasting formula reduces the need for frequent reapplication

- Compatible with most types of materials

- Translucent white color makes it less noticeable on surfaces

Cons:

- May not be suitable for extremely high temperatures or heavy-duty applications

- The small size of the tube might not be enough for larger projects

The Super Lube-21030 stands out in the market for its exceptional quality and reliability. With its synthetic formulation, it provides a consistently high performance that protects and maintains parts effectively. The translucent white appearance allows it to blend in seamlessly, avoiding any unsightly grease marks.

Moreover, the convenient 3 oz. size makes it easy to handle and apply, even in tight spaces. Whether you’re a professional mechanic or a DIY enthusiast, the Super Lube-21030 is an excellent choice for ensuring that your equipment runs smoothly without any hiccups. Its lightweight and compact design, coupled with its long-lasting benefits, make it an indispensable tool in any maintenance kit.

To buy this product, click here.

Permatex White Lithium Grease

The Permatex 80345 White Lithium Grease is a premium lubricant designed for multi-purpose use in a convenient 1.5 oz. size. This high-quality grease is perfect for ensuring your gears and moving parts operate smoothly without friction or wear.

Pros:

- Provides superior lubrication and durability in any weather and most temperatures.

- Protects against rust and corrosion.

- Reduces friction on moving parts.

- Easy to apply with pinpoint accuracy.

Cons:

- May not be suitable for all types of bearings or plastics.

- Small size may not be sufficient for larger projects.

When it comes to maintaining machinery, the Permatex White Lithium Grease stands out for its reliability and effectiveness. Its white color makes it easy to see where the product has been applied, ensuring thorough coverage. Manufactured by Permatex, a trusted name in the industry, you can be confident that you’re using a product designed for peak performance.

Moreover, the practical dimensions of the product make it a handy tool for any DIY enthusiast or professional. Measuring 8.0 inches in height, 3.81 inches in width, and 1.13 inches in length, with a weight of merely 0.000625 pounds, it is compact enough to fit in any toolbox yet substantial enough to handle a variety of applications. Whether you’re looking to ensure smooth operation of garage door tracks, hinges, or even marine applications, the Permatex 80345 White Lithium Grease is an excellent choice.

To buy this product, click here.

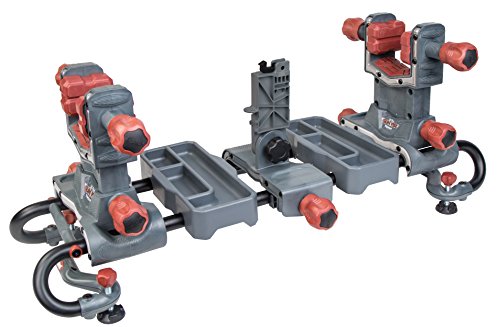

Tipton Best Gun Vise

The Tipton Best Gun Vise is an essential tool for anyone involved in the care, maintenance, or customization of firearms. Designed with a secure adjustable cradle, this vise accommodates a wide range of firearms, making it versatile for various gunsmithing tasks. Its red/grey color scheme not only adds a professional look to your workspace but also enhances visibility during intricate work. Additionally, the vise includes storage compartments for organizing cleaning supplies and tools, ensuring everything you need is within reach.

Pros:

- Adjustable cradle securely accommodates various firearm types.

- Integrated storage compartments keep tools and cleaning supplies organized.

- Durable construction ensures long-lasting reliability.

- Lightweight design (0.661386786 Pounds) for easy maneuverability.

- Attractive red/grey color scheme enhances workspace aesthetics.

Cons:

- Limited color options may not suit all personal preferences.

- May require additional padding for extremely delicate firearms.

The Tipton Best Gun Vise stands out as a top choice for gun owners and enthusiasts looking for a reliable, versatile tool for firearm maintenance. With its secure adjustable cradle, it easily accommodates a wide variety of firearms, from handguns to rifles, ensuring a perfect fit for any gunsmithing project. The storage compartments are a thoughtful addition, allowing users to keep their cleaning supplies and tools neatly organized and within easy reach. This feature not only saves time but also prevents the loss of small, critical components during maintenance sessions.

Moreover, the vise’s lightweight design and durable construction make it an ideal choice for both amateur and professional gunsmiths. It’s easy to transport and set up, yet sturdy enough to handle the demands of regular use. The red/grey color scheme not only looks professional but also helps to quickly identify tools and components against the contrasted background. Despite its few limitations, such as the limited color options and potential need for additional padding for very delicate firearms, the Tipton Best Gun Vise offers great value and performance, making it a must-have for anyone serious about firearm maintenance and customization.

To buy this product, click here.

Lucas Oil Products White Lithium Grease

When it comes to maintaining moving parts, the Lucas Oil Products LUC10533 White Lithium Grease is a top-tier choice for professionals and DIY enthusiasts alike. Known for its high quality and reliability, this product ensures that your machinery operates smoothly and efficiently.

Pros:

- High-quality white lithium grease formula for optimal performance

- Comes in a convenient 8-quart size for extensive use

- Easy application with a user-friendly packaging

- Manufactured by the reputable Lucas Oil brand

- Great for a wide range of applications, including automotive and household tasks

Cons:

- May not be suitable for all types of materials or surfaces

- At 0.5 pounds, the weight might be a consideration for those requiring a portable solution

- Comes in “No Color”, which may not be preferred by users who need visual identification of lubrication

The Lucas Oil Products LUC10533 White Lithium Grease stands out in the market due to its exceptional quality and versatility. The product is designed to reduce friction in moving parts, preventing wear and extending the lifespan of machinery. Whether you are working on automotive bearings, hinges, or even household items, this grease is equipped to handle the job with ease. The lack of color in the grease is advantageous for applications where cleanliness and non-staining are priorities.

Notably, this grease is produced by Lucas Oil, a manufacturer known for their commitment to creating high-performance products. The dimensions of the container (Height: 8.4 Inches, Width: 1.9 inches, Length: 2.25 Inches) make it compact enough for easy storage yet sufficient for multiple applications. Despite its few limitations, the Lucas Oil White Lithium Grease is a solid investment for anyone seeking a reliable lubricant for general use or specific tasks.

To buy this product, click here.

Frequently Asked Questions

What Is The Best Grease For Bench Vises?

The best grease for bench vises is one that provides high lubricity, resistance to water and contaminants, and durability under heavy loads. Super Lube-21030 Synthetic Multi-Purpose Grease and Permatex 80345 White Lithium Grease are excellent options for ensuring smooth operation and longevity of your bench vise.

How Often Should I Lubricate My Bench Vise?

It is recommended to lubricate your bench vise every six months or after extensive use. Regular lubrication helps maintain smooth operation and prevents rust and wear. Adjust the frequency based on usage and environmental conditions for optimal performance.

Can I Use White Lithium Grease On Bench Vises?

Yes, white lithium grease, such as Permatex 80345 or Lucas Oil Products LUC10533, is suitable for bench vises. It provides a thick protective layer that resists water and heat, ensuring smooth operation and protection against corrosion.

Is Synthetic Grease Better For Bench Vises?

Synthetic grease, like Super Lube-21030, is often better for bench vises as it offers superior performance over a wide temperature range, longer lubrication intervals, and better resistance to oxidation and corrosion compared to conventional greases.

What Grease Is Safe For All Bench Vise Materials?

Super Lube-21030 Synthetic Multi-Purpose Grease is safe for all bench vise materials. It is non-toxic, dielectric, clean, and clear, making it an ideal choice for various materials, including metals and plastics, without causing damage or degradation.

How To Apply Grease To A Bench Vise Properly?

To properly apply grease to a bench vise, clean the vise jaws and screw mechanism, apply a thin layer of grease to the screw and moving parts, and wipe away excess. Ensure even coverage for smooth operation and avoid over-greasing to prevent attracting dirt.

Conclusion

Choosing the right grease for your bench vise is essential to maintain its performance and durability. Throughout this post, we’ve looked at various options suitable for different vises like the wilton general purpose bench vise, the wen bench vise, and the mytec drill press vise.

Each product, from the yost vises 750-di to the tipton ultra and best gun vise, brings its unique features to the table. For those in the bike repair or gunsmithing field, we’ve discussed options that cater specifically to your needs.

Remember, when selecting a grease, consider the specific requirements of your vise. The super lube and permatex white lithium grease are great for general use, offering ease of application and a reliable performance. Lucas oil’s white lithium grease stands out for those looking for a larger quantity.

Proper lubrication is not just about smooth operation; it’s about preserving your tools for years to come. So, take a moment to assess your needs, match them with the right product, and keep your bench vise in top condition. Simple steps today can lead to long-lasting benefits for all your projects.

Keep it smooth, keep it simple, and get the job done right.