Best 4×8 CNC Router

By:

Tools Guidance

Published:

February 16, 2026

CNC is an acronym for Computer numerical control. These devices are used in a variety of industries, including woodworking, plastics, and metalworking. CNC machines are used to do the job of skilled workers, who are more expensive to employ, and they are also used to make products that are too complicated to be created by hand. The price of CNC machines varies depending on the size, whether they can do 3D carving, and the quality of the construction. If you’re looking to get the best 4×8 CNC router, you’re probably interested in making some pretty big stuff, and you might want to get in on the fun of milling your own pieces. Maybe you have a fondness for making things out of wood, metal, or polymer. You might have an artistic side, and you want the satisfaction of creating your own designs. You might want to build something for your home, or for your work.

What is a 4×8 CNC Router?

The CNC router is a type of machine that performs a variety of functions. The router can be used to remove or add material from a piece of material such as wood or metal, to create objects with the material. The most common material for CNC routers is wood. The router can be used to create a variety of objects such as signs, cabinets, and even furniture. It can also be used to create shapes on pieces of material, which can later be used for other purposes. The router can also be used to mill open parts in a piece of material. CNC router is a tool that is used to cut wood and metal using computer assisted design. A 4×8 CNC router uses a variety of bits to achieve different shapes and cuts on the items it is being used on.CNC router has a gantry and uses a computer system to cut the items placed on the gantry. The 4×8 cnc router uses a variety of bits that have different shapes to achieve different cuts on the items. The bits used by the cnc router are changed by a cutting tool changer. This routers are really easy to use as they can be operated through a computer.

Top 5 Best 4×8 CNC Routers Are Given Below

CNC is short for Computer Numerical Control. CNC machines are used in the film industry for tasks such as making custom labels, stickers, and logos. They are basically machines that contain the software to create 3D models. There are several various types of CNC machinery and they range in price depending on the capabilities and quality. Intelligent people know that if you want to buy a 4×8 CNC router, the most important thing to do is to check the reviews. After all, what’s the point of buying a 4×8 CNC router that doesn’t do what it’s supposed to? In particular, what’s the point of buying a 4×8 CNC router that isn’t built to last? If you want to buy the best 4×8 CNC router, you should check out the following reviews:

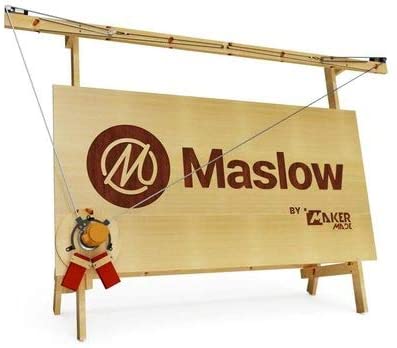

1. Maslow CNC Router DIY Router Kit

If you are interested in getting a CNC machine, you probably know that there is no shortage of options available. You can get a kit and build it at home, or you can even get a pre-assembled one. But if you’re looking for a specific kind of CNC machine, you may not even realize there’s one in existence. That’s what makes the Maslow CNC router so intriguing. The Maslow CNC Router is a cool new router that can be used for a wide range of DIY projects. The router features a built-in X-carve and laser engraver, as well as a five-inch touchscreen, an SD card reader, and an Ethernet port. This makes it easy to integrate the router into a CNC build of your own design. It may also be used with the included software to build your own CNC designs and projects.

Key features :

- It is an A-Zaxis router machine.

- It gives a 4×8 foot high performance.

- This Router is of Open source.

- It is chain driven.

- It is a very strong alternative.

- It gives the 100% guarantee of satisfaction.

Technical Parameters:

| Produced by | makermade |

| Weight | 11.68pounds |

| Cutting area | 4′ x 8′ (~1.2 x ~2.4 m) |

| Rated power | 100-240 volts, 50-60Hz |

| OS | Windows, OS X, Linux |

Standard Accessories:

- Collet wrench.

- T-handle wrench.

- Quad adapter.

- Centering tool and pen.

- Screws.

- Adapter for vacuum.

Application:

- At first unpack the machine.

- Then set up the machine according to the guide given with the machine.

- Now you must have a file to test run the CNC machine, then after test running you must go for the next step.

- Then after setting it on the main board where you want to do the design press the button and run the CNC machine.

Advantages:

- It is capable of curving the surface.

- It is an affordable and accessible router.

- The cut depth is adjustable by the machine.

- It is great for beginners.

- The instructions given on this router are easy to follow.

- The setup process is really easy.

- It is a great product with outstanding customer service.

- It cuts precisely.

- It is great at making signs.

- It is an excellent product.

Related: Best Home CNC Machine

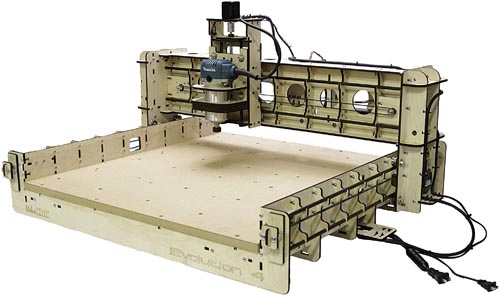

2. BobsCNC Evolution 4 CNC Router Kit with the Router

Have you been looking for a CNC Router that is easy to use? That’s not the case with the BobsCNC Router kit with the Router. Its open source design means that you can modify the software to suit your needs. For example, the straight-line and circle cutting is great if you want to make a jigsaw puzzle to display on the wall. But you don’t have to stop there. You can also utilize the CNC Router for cutting custom designs into pieces of wood or plastics. In the last few years, CNC milling has become increasingly popular as a tool for hobbyists to use in their workshop or garage. One of the reasons it has become so popular is because of the range of materials and projects you can make with it. Unlike traditional woodworking or metalworking, milling machines can be used to make a wide variety of products that would be difficult or impossible to make with normal tools.

Key features:

- It has a laser-cut rigid framing system.

- It supports all the rail systems.

- It drives into the X and Y axis.

- It is 115Volts.

- Its cutting area is 24″ x 24″.

Technical Parameters:

| Producer | BobscNC |

| Weight | 58 Pounds |

| Power supply AC | 12 VDC 8 amps |

| Wattage | 600 |

| Input | 110 v |

Standard Accessories:

- Collet wrench.

- T-handle wrench.

- Quad adapter.

- Centering tool and pen.

- Screws.

- Adapter for vacuum.

Application:

- At first unpack the machine.

- Then set up the machine according to the guide given with the machine.

- Now you must have a file to test run the CNC machine, then after test running you must go for the next step.

- Then after setting it on the main board where you want to do the design press the button and run the CNC machine.

Advantages:

- It is budget friendly.

- It is easy to use.

- It is quite easy to assemble.

- The sheerness is good.

- It is a really great choice for the beginner’s.

- It is a great starter machine.

- It is an excellent product.

- It is worth the money.

Related: Best Circular Saw Blade

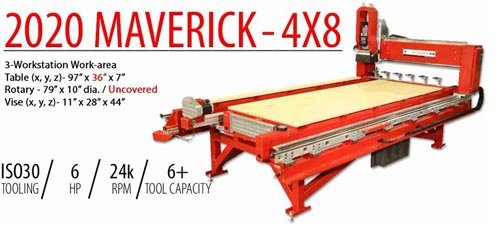

3. Maverick 4×8 Wood CNC Machine

The Maverick is a 4×8-inch CNC milling machine that sits at the top of the Shopbot CNC router line, and it’s quickly becoming a standard in small manufacturing operations. This is a terrific example of a simple, yet highly functional design that’s easy to use, and the machine quality is superb. The router has been around for some time now, and they’re just getting better and better. This time we have a professional grade model that is rated to run with 4 collets. It supports both G-code and its own proprietary language. It’s equipped with a spindle that can spin and it’s compatible with a wide range of accessories. Plus, it’s capable of handling both soft and hard wood. The Maverick is a CNC router that is designed to cut out small parts quickly. The machine’s small footprint and smooth aluminum bed make it perfect for the job. The machine is also easy to use, with an incredibly intuitive interface.

Key features:

- It is a spindle and auto tool change.

- It is auto controlled.

- The frame design is amazing.

- It is of smart tool features.

- Made in the USA.

- 1 year warranty.

Technical Parameters:

| Producer | Maverick |

| RPM | 24k |

| Horse power | 6HP |

| Total capacity | 6+ |

Standard :

- Collet wrench.

- T-handle wrench.

- Quad adapter.

- Centering tool and pen.

- Screws.

- Adapter for vacuum.

Application:

- At first unpack the machine.

- Then set up the machine according to the guide given with the machine.

- Now you must have a file to test run the CNC machine, then after test running you must go for the next step.

- Then after setting it on the main board where you want to do the design press the button and run the CNC machine.

Advantages:

- Fastest and simplest way to hold down the sheets.

- It is easy to set up.

- So faster Than any other products.

- It is made in the USA.

- It is budget friendly.

- It is quite easy to assemble.

Related: Best Table Saw Fences System

4. CNC Router 1325 with 4×8 Rotary Table

While 3d printers have become increasingly popular in recent years, the CNC router is still the go-to machine for shaping wood, metal and plastic to create a wide variety of objects. If you want to create wood projects at home, you might want to consider investing in a CNC wood router a special type of device that can cut complicated patterns and shapes into wood pieces with accuracy and precision. Think of it as a more advanced version of the carving tools you can find in many woodworking shops. Today, we’ll look at the STYLECNC CNC wood router, a high-quality device that can help you create professional-looking wood projects.

Key features:

- It contains the T-slot table.

- It has Manual lubrication process.

- The Tool sensor is calibration.

- It has the japanese OMRON limit switch.

- It gives the best cable, flexible and fire resistant.

- It is of 3KW water cooling with

- spindle of 24000rpm.

- It is a 3.7KW Fuling inverter.

- It has the NK105 DSP controller.

- It includes the Taiwan HIWIN 20 square linear guide.

- The helical rack is transmission for the X, Y axis, which is powerful and stable as well.

Technical Parameters:

| Brand | Stylecnc |

| Frame | Welded structure |

| Size of table | 4×8 |

| Surface of Table | T-slot table |

| Maximum power consumption | 3.25KW |

Standard accessories:

- It is an automatic tool changer.

- It has a vacuum pump.

- It has the dust collector.

- It has a vacuum table.

Application:

- At first unpack the machine.

- Then set up the machine according to the guide given with the machine.

- Now you must have a file to test run the CNC machine, then after test running you must go for the next step.

- Then after setting it on the main board where you want to do the design press the button and run the CNC machine.

Advantages:

- It supports A/C code format.

- It has four new linkage motions.

- It has intelligent processing memory.

- It has strong anti- interference.

- It is quite easy to assemble.

- The sheerness is good.

- Best choice for the beginner’s.

- It is a great product with outstanding customer service.

Related: Best Dust Collector

5. 4×8 ATC CNC Router Under $20,000

CNC routers use a variety of different technologies to fabricate complex parts, but they all share one thing in common: a computer numerically controls the router’s movements. Typically this is only done with the larger, more expensive machines, but a Chinese manufacturer is trying to change that. ATC Technology has a new CNC router under $20,000 that uses ATC’s proprietary technology, which includes a force sensor that measures the router’s cutting force and a computer that predicts the machine’s movements based on the force sensor’s reading. While the market for routers has always been a very niche-oriented one, we were interested in finding out whether a quality machine could be purchased for less than $20,000. We searched for several months for machines that fit our criteria and could be purchased for less than $20,000.

Key features:

- It has a heavy machine body which can take heavy duty.

- It is 9.0KW.

- There is an Automatic Tool Changer spindle.

- It has the controlling system of Syntec.

- The Japanese Yaskawa 850W servo motor and the drivers.

- It is an 11KW Delta Taiwan inverter.

- The Taiwan HIWIN is of 30 square rails.

Technical parameters:

| Maximum working height | 300mm |

| Working air pressure | 0.6mPa |

| The spindle speed | 24000r/min |

| Positioning cylinder | 3 |

| Weights | 24000kg |

Standard Accessories:

- It is of double layer 30mm.

- It is chinese easy servo.

- It has the non-return valve filter.

- It has HSD air cooling technology.

Application:

- At first unpack the machine.

- Then set up the machine according to the guide given with the machine.

- Now you must have a file to test run the CNC machine, then after test running you must go for the next step.

- Then after setting it on the main board where you want to do the design press the button and run the CNC machine

Advantages:

- It is an automatic tool changer.

- It has the tool sensor.

- It has the standard plywood case.

- The soil structure is quite good.

- It is budget friendly.

- Best choice for the beginner’s.

Related: Best Compact Router

Why 4×8 CNC Routers?

Big and powerful, that’s the first impression that comes to mind when you see a 4×8 cnc router. Yes, they are big. The size of these machines is almost the same as the size of a car which makes them powerful; they are also easy to use. This makes them very popular with people who are just starting out with making items and figuring out how to use a router. If you are one of these people, then you should get a 4×8 cnc router. There are many types of CNC Routers in the world, but in this article we are going to talk about 4×8 CNC Routers. They are both large and powerful machines and they are extremely versatile, but there are also a lot of differences between them and smaller CNC Routers. So if you were considering upgrading to something larger, there are plenty of reasons to do so. If you have never used a CNC Router before, you may be wondering what the difference between a 4×8 CNC Router and a smaller CNC Router is.CNC routers are an invaluable addition to any workshop, as they allow you to carve designs quickly and easily. Most can cut materials such as wood, plastics, fiberglass, and even metal. Of course, they all have different capabilities, so it pays to shop around and find one that best matches your needs. If you want to use the CNC router to create small pieces that do not require precision and are not mission critical, a smaller router will do.

How To Choose The Best 4×8 CNC Router Machine And Kit

The tips for choosing the CNC router machines are given below:

Weight of the Machine :

The weight of the CNC routers is not a very important factor to consider when you are going to buy one because the weight is not going to affect the performance of the machine. It does, however, have an impact on the portability of the machine and the ease of moving it from one location to another.CNC routers used to be very large machines, weighing up to and over 10,000 pounds. However, the latest generation of machines have been redesigned to be smaller and more compact. You can now get a router that weighs less than half of what their older counterparts did! This is a great thing for hobbyists and small businesses, as it allows the machines to be lifted and moved by a single person. In this day and age of technology, where almost anything is possible, finding the right router has become slightly difficult. We have hundreds of products, But which one is the best? How much does it cost? What are the specifications? We are here to answer these questions and more, In order to give you the best advice possible !

The Working Radius:

Modern software allows us to design a blueprint and then send the cutting job to the router. This is a huge improvement over the older machines that required you to manually move the router around and trace the path to cut. However, it is important to keep in mind how much space you have to work with. Some machines are larger than others, and this can limit the size of the objects you are able to cut.CNC routers are a good choice for both home users, and small businesses that want to get into woodworking and manufacturing. But with so many models to choose from, how can you be sure you’re buying the right one for you? It’s important to look at a few key specs, such as working radius – the distance the router bit will cut into the wood before the bit needs to be realigned. The larger the router’s working radius, the more freedom you have to work on larger pieces of lumber.

CNC Router Features

A CNC router is a machine that is used in making 3D shapes out of wood, plastic or other material that is similar to paper. The machine is called CNC because it contains computer numerical control, which is used for making 3D shapes. It is used for making decorative and useful items out of wood or other similar material. The machine is also called a CNC router machine.CNC routers are used to make and cut different types of materials. They can be used to cut wood, plastics, and other materials.

- CNC routers come in a variety of sizes. From the smallest bench top models to the largest industrial models, they can be found in almost any size.

- The CNC routers of today are more feature-filled than ever. Some models have a vacuum attached, and others have multiple spindles.

- CNC routers are used in a variety of industries, from construction to manufacturing to the arts.

- The most common types of CNC routers are vertical, horizontal, and rotary. Each has its own unique features and capabilities.

Table Size:

To cut a flat panel of wood, you need to figure out the size of the panel. The first thing you need to do is to make sure you have the right tools. Get a measuring tape and a calculator. Mark the measurement of the panel on the tape measure. Calculate the total width of the panel. You can then use the calculator to determine the number of inches in the width of the panel. This number represents the width of the wood piece you need to cut for the panel.CNC routers are machines that are used to create 3D objects from any shape and size. They are made in a way that you can control them from a computer to create the desired object. CNC routers are affordable considering the roles they play in the industry. In this article we picked out some of the popular models and talked about their table sizes.

Disposable Table Top:

Ready to upgrade your workshop? A CNC router is a good choice if you need a versatile piece of machinery that will help you in a variety of tasks. The router is lauded by many woodworkers and home improvement experts as being one of the most effective tools in the workshop. For that reason, you will likely want to consider investing in one. However, it is important to know what you are looking for before you make that investment. The CNC Router is a great tool for businesses who want to cut down on the costs of using disposable materials to create product prototypes. The CNC Router is a reliable, easy to use machine that any business can use to create the products they need today as well as a tool for building the products of the future.

Perforated Table Top:

With the fall of the CNC routers being low-priced, the price of these machines has been reduced to within the reach of a hobbyist. Early CNC routers were known as a high-end machine. However, these machines have been popular for years, and they are now widely used by hobbyists and businesses for a variety of applications. CNC routers can cut a wide variety of materials and are often used in manufacturing industries.CNC routers are tools that can be used to create almost any shape. These tools take the design for a piece of furniture, for example, and transform it into a solid piece of wood. CNC routers can be used to transform even more than wood. Shapes can be cut out of metal, plastic, and even stone. They are commonly used to create furniture, but can be used to create anything from dimensional signs to artistic shapes.

FAQs:

How do you use a CNC ROUTER?

CNC Routers are an essential part of the woodworking industry, and they are used by both hobbyists and professionals to create unique and decorative pieces of wood. CNC Routers can be used to cut wood, plastic, and nearly any material, and can be used to create just about any shape or design.CNC routers are used to make engraved signs, engrave inlays for furniture and create personalized signage. There are many different types of CNC routers on the market, and they all have their own unique features. When choosing a machine, you must consider your project and what you intend to do with it.

What should I do with my CNC Router?

This is one of the most common questions we get at our blogs, and the answer is always “it depends”. If you have a router and you’ve only used it for one project, then it doesn’t have enough experience yet to know what it likes best. Also, your router is a tool, not a toy. Treat it with respect and you will get the best performance. That being said, there are a few things that you can do to maximize your router’s potential and improve the quality of its work.

How long a CNC router does take?

CNC routers are very versatile tools. They can be used to create a wide variety of objects from hard materials, such as wood and plastic. They are also used on a regular basis to make precise cuts on soft materials, such as leather and fabric. But how long does a CNC router take to create a project? That depends on a lot of factors.CNC routers are available from a variety of manufacturers. While most CNC routers are relatively easy to set up and use, there are a few things you should know before you buy one. For example, some CNC routers are sold as kits, which you must assemble yourself. Other CNC routers are sold preassembled. Generally, pre assembled CNC routers are more expensive than kits, but require less time and effort to set up.

Can you use CNC Bits in a router?

There are three primary components to most CNC routers: the spindle, the router bits and the g-code bitstreams. The spindle is a device that drills holes or cuts the material using a spinning tool. It is the part of the router that you connect the router bits to. The router bit is a cutting tool. It is the part that produces the actual hole or cut. The g-code bitstream is the program that tells the CNC router what to do. It is typically created using a CAD or CAM program on a desktop computer or laptop. While you may not be able to use your router for CNC routing, you can use CNC bits in your router. A CNC router is a machine that is used to cut wood, plastic and other materials into accurate shapes and designs. CNC bits are similar to router bits, but they are specifically designed for use in CNC machines. CNC bits are held in place by a collet, much like your router bits are held in place by your router collet. While you can’t use your router for CNC routing, you can use CNC bits in your router to cut materials in a wide variety of shapes.

Is a CNC router worth it?

A CNC router is a machine that is used to cut and shape a variety of materials such as wood, metal, plastic and foam. CNC stands for computer numerical control, which basically means that the router is controlled by a computer. The computer can be very basic or advanced, depending on the type of CNC machine that you’re looking at. A CNC router is very much worth using because it makes work easier.

Final Verdict

There is certainly a lot of competition when it comes to 4×8 CNC routers, but it’s important to remember that just because you are getting a large model doesn’t mean you are getting the best model. Here in our blog we mentioned a few things to keep in mind when you are looking for a router. Maslow CNC Router DIY router kit is the best router of all 5. Hope you read the whole blog and like it and let us know about your perspective about the routers.

Latest

Get a quote

If you need assistance, send us an email. We try to answer all requests for assistance within 24 to 48 hours.

Get Quote